Trajectory Mixing – Refractory Materials

Less water. Shorter mixing time. Minimal frictional heat.

Technical Benefits

The goal is a reproducible mixing window for demanding formulations – with high homogeneity, low heat input, and reduced downtime.

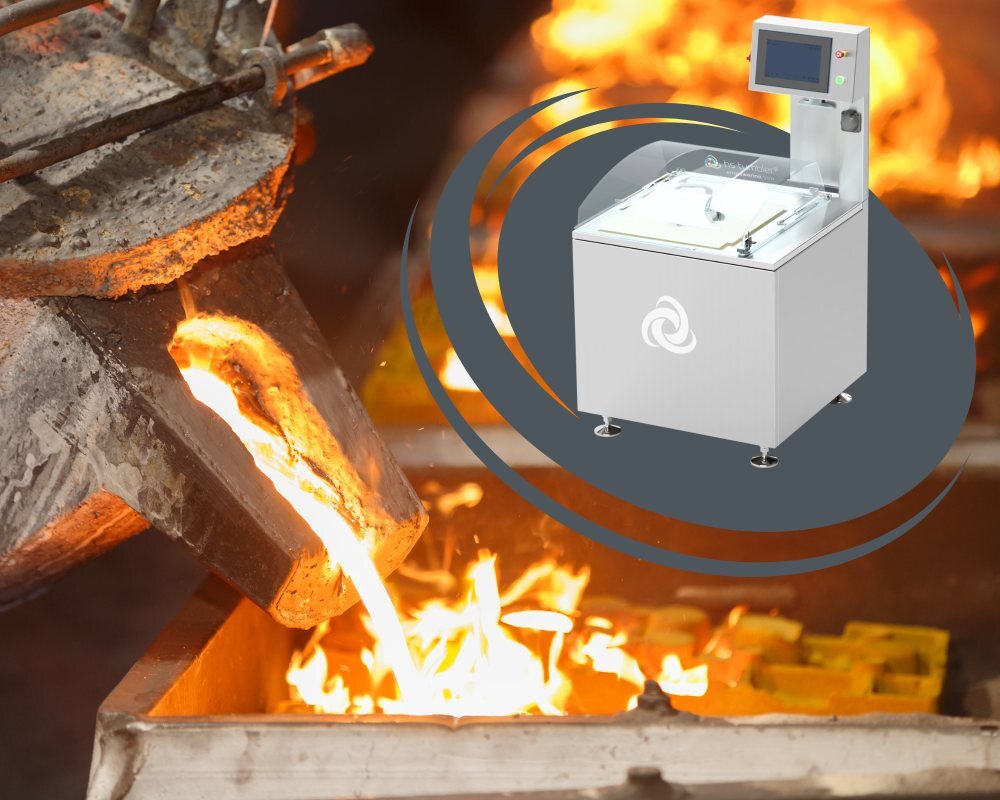

Mixing Refractory Castables

K1 in operation with 4 L container

Consistent distribution, even with demanding components, with stable consistency control.

Reduced temperature rise supports stable material structure and reliable processing.

No mixing tools in contact with the product. Fewer wear points and reduced process disturbances.

Potential to reduce water and additives (formulation-dependent) while achieving defined flow behavior.

Process steps can be simplified, depending on formulation and plant layout.

Adjustable via trajectories, mixing time, and water-addition profile for a reproducible mixing window.

Clear batch control supports traceability, documentation, and reproducible process parameters.

Enclosed, tool-free design. Fast cleaning and changeover with defined process control.

TM – Expanding Process Windows

Two motors (X/Y) generate freely parameterizable trajectories. The bulk material forms an adjustable cross-flow pattern. Atmosphere control (vacuum / inert gas) is optionally possible.

Control Variables (Process Recipe)

- • Frequencies fₓ, fᵧ; Amplitudes Aₓ, Aᵧ; Phase shift δ

- • Mixing time, water-addition profile, additive dosing

- • Atmosphere: vacuum / inert gas (optional)

- • Fill level, tilt angle, batch mass (machine-specific)

Note: Quantitative evidence (e.g., water reduction, cycle-time reduction vs. reference mixers) is formulation- and application-dependent and is generated via structured benchmarks.

Mixing Principle (Animation)

Trajectories directly influence cross-flow formation, homogeneity, and consistency.

Go to interactive simulation →High homogeneity through cross-flow formation with minimal frictional heat.

Fewer wear points; no mixing tools in the material, reduced downtime.

Parameterizable trajectories support a reproducible mixing window.

Enclosed design; no dust discharge, fast changeover.

Typical Applications

From small functional parts to large-volume, complex shapes – especially for abrasive, demanding mixes.

e.g., for precision parts as well as additional cast bodies and shaped parts.

Formulations with a high share of hard aggregates / high abrasiveness.

Mixes with fibers, lightweight aggregates, or sensitive additives (formulation-dependent).

Clear batch allocation (quality, documentation, process parameters).

Direct Comparison: Conventional vs. Trajectory Mixing

Actual effects depend on formulation, equipment, and process. This comparison highlights typical technical mechanisms and expected differences.

Typically several minutes, depending on formulation and tool geometry.

Abrasive aggregates load agitators, paddles, and seals.

Heating from tool/material contact can narrow the process window.

Tools and mixing chamber require cleaning; downtime may increase.

Risk of abrasion/particles from tools or coatings.

Short cycles are possible; goal is reproducible homogeneity within the mixing window.

Tool-free in the product; focus shifts to container/inner wall as main contact area.

Minimized frictional heat supports stable consistency and material structure.

Fast cleaning without mixing tools; reduced downtime and dust discharge.

Trajectories as a control variable for cross-flow patterns, homogeneity, and flow behavior.

Less water. Shorter mixing time. Minimal frictional heat.

Let’s start with a pilot trial. Together we define a test matrix and derive robust, application-specific KPIs.